Thor Diesendorf - Founder & Director of Thor's Hammer // Meet the Team

February 2021

Thor Diesendorf is the owner of Thor’s Hammer, one of Canberra’s largest recycled timber suppliers. Thor began sourcing timber from local demolition sites to make custom furniture and kitchen tops back in the 90’s.

Read on to learn more about how Thor’s Hammer came to life, including where the business name came from, the role that Thor’s mentor played in his life and career, the big move across Canberra and what makes Thor’s Hammer so widely known as a great place to work. There’s also special mention about a particular team member, who although is greatly loved, isn’t always the most productive.

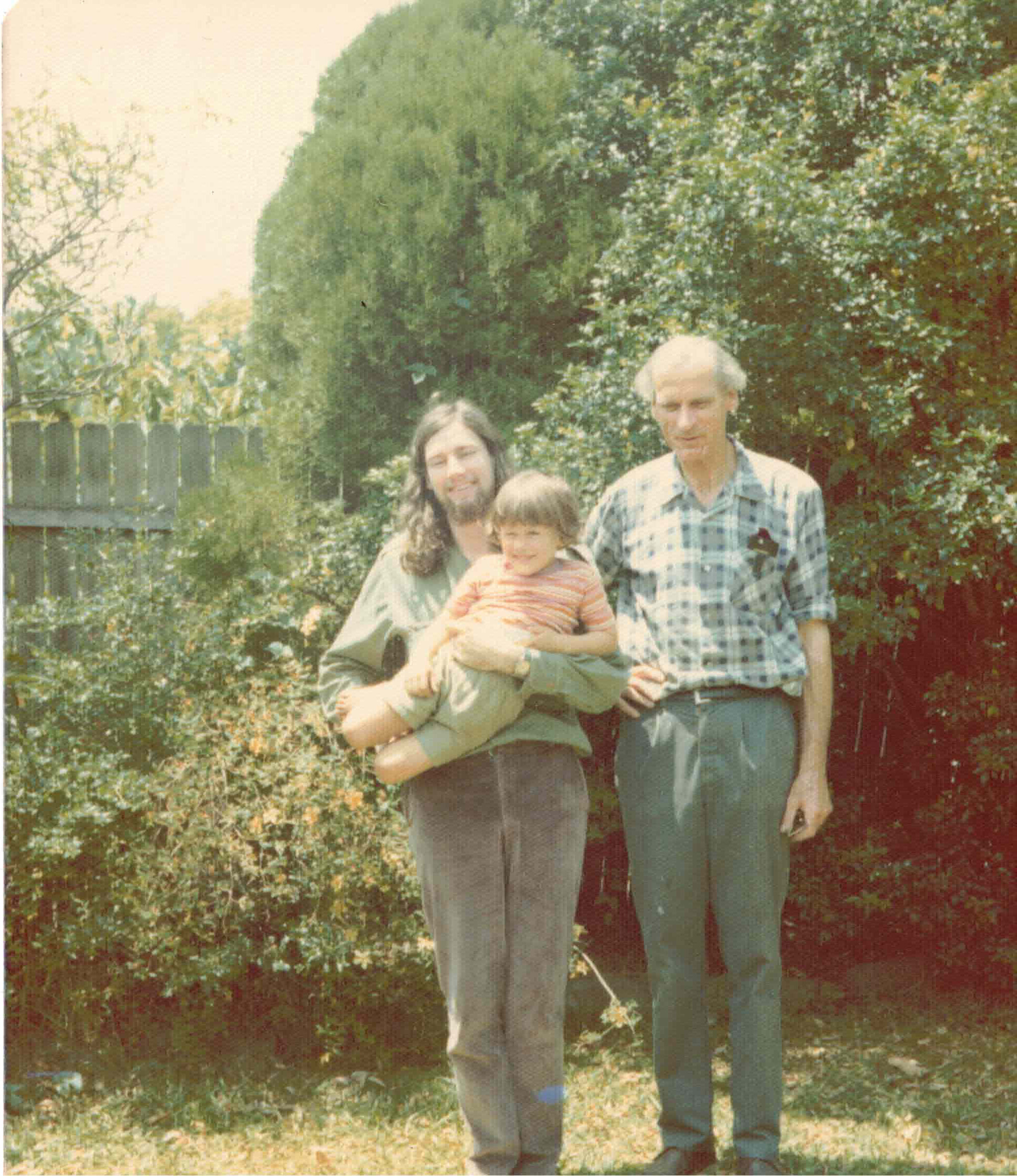

Thor’s earliest memory of working with timber goes back to when he was a child watching his grandfather in the shed. Whether grandad was making fine furniture, fixing up old cars or making things for his boat, Thor attentively watched and occasionally passed tools, swept sawdust and held boards steady. He described being allowed in the shed and watching the process as ‘heaven.’ Son to an astrophysicist and mathematician father, Thor’s interest in sustainability arose as he listened to his parents and his dad’s colleagues talking about the state of the world and their research.

Images (left to right)

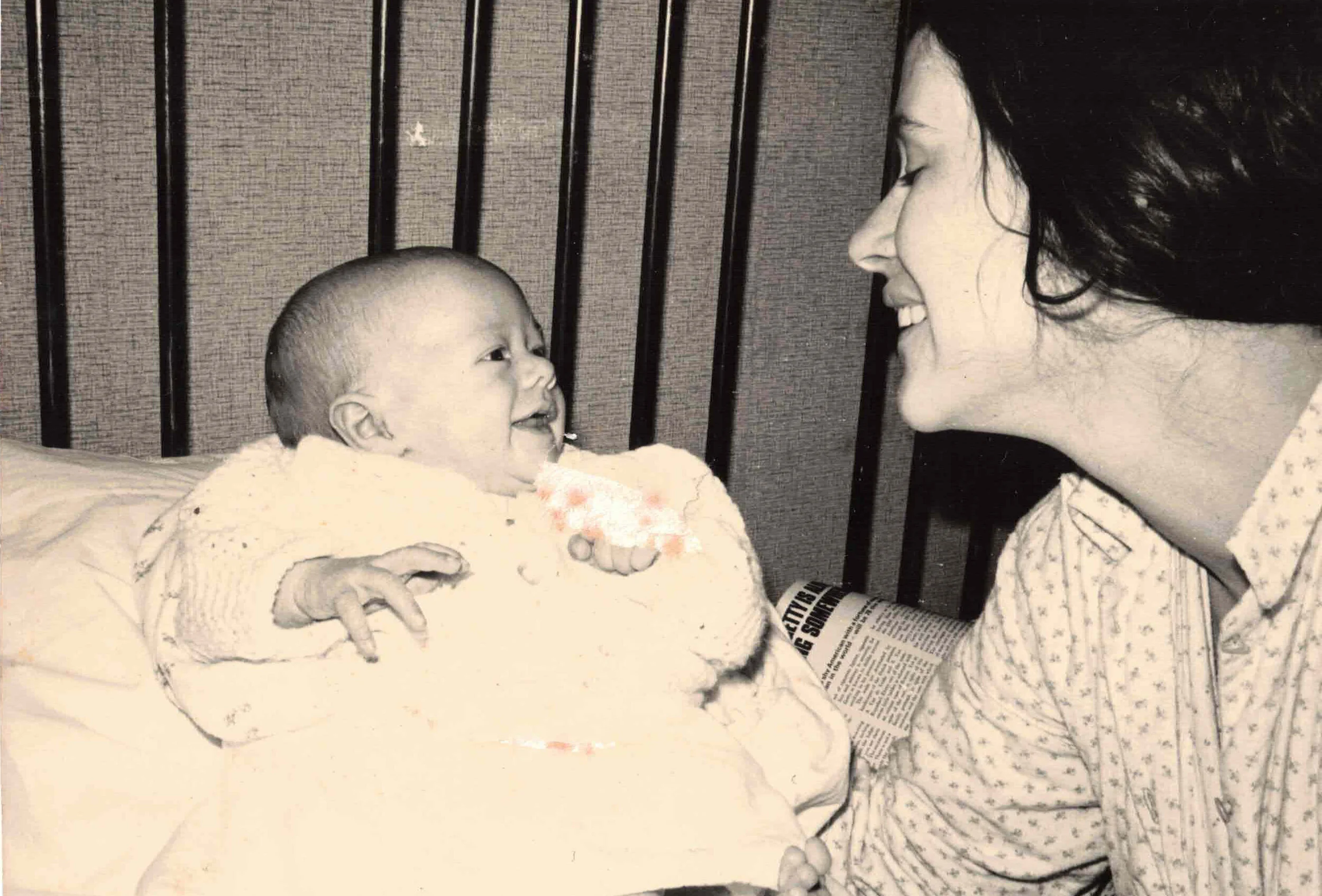

Baby Thor with mum Ann, 1971

Uncle Peter, Thor and Thor’s granddad Tom

4 year old Thor with dad Mark, little brother Danny, mum Ann, 1975

Thor and True in the landcruiser, 1990

Thor describes his greatest mentor, Paul Lynzaat, as a carpenter, joiner and most importantly, a great teacher.

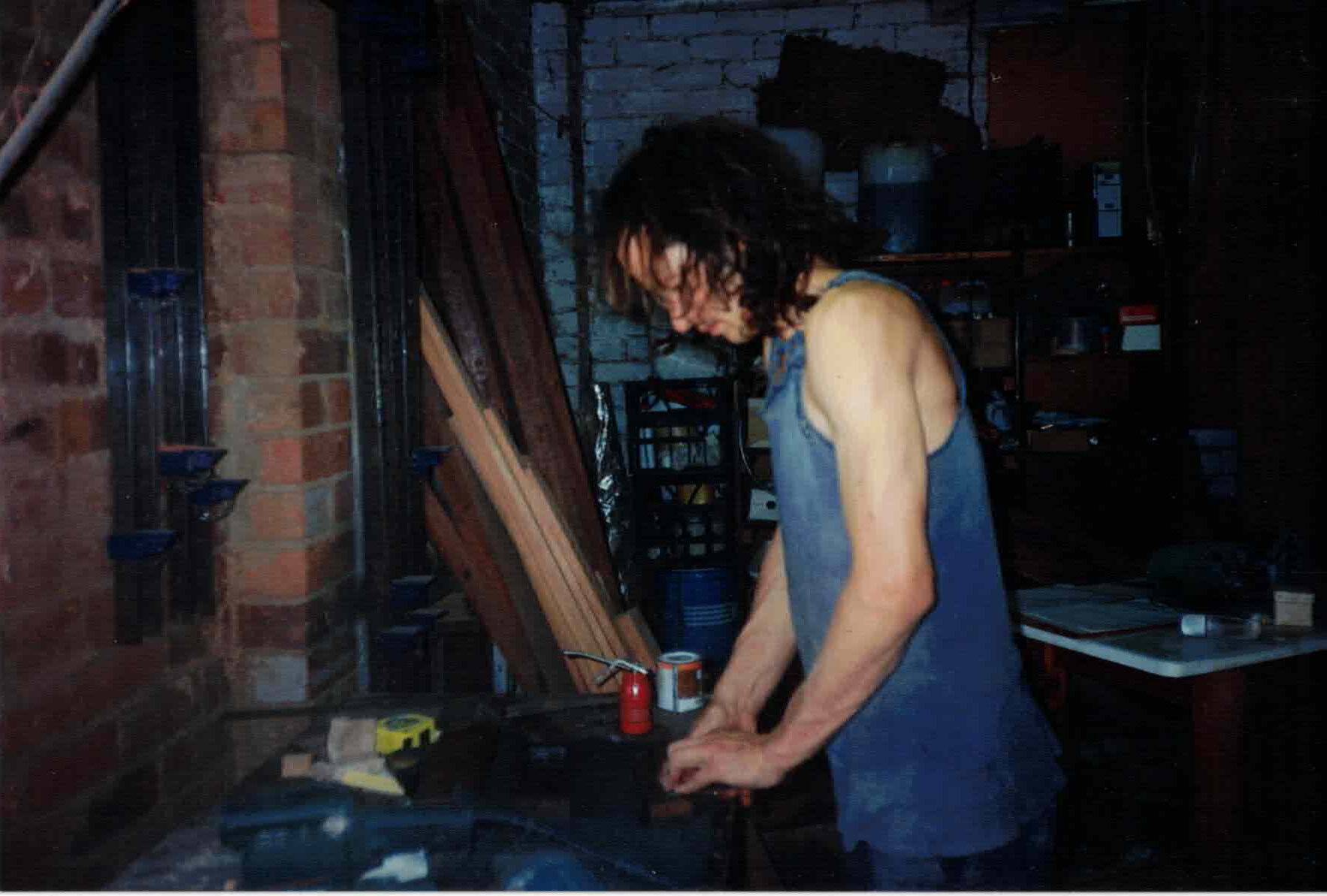

Paul Lynzaat pictured at Thor’s Hammer at Brickworks.

“I would have been 20 when I visited him for a cuppa to get advice on knocking up some painter’s trestles for a job I was doing down the coast. I ended up spending two weeks of evenings in the old bus he had set up as a carpentry workshop learning how to make the painter’s trestles properly with wedged mortise and tenons, hand forging the hinges and using fine grained recycled Oregon, some of which we grabbed out of his roof - apparently you don’t really need all the braces they used to put up there! ”

At the time, Paul was inventing a compressed earth block machine in his garage. Earth blocks, also known as pressed earth blocks or compressed soil blocks, are a building material made primarily from damp soil compressed at high pressure to form blocks. Paul’s earth blocks are in the Tidbinbilla Visitor’s Centre, as well as many rural homes around Canberra.

Thor says that it was Paul who got him started on making joinery, furniture and kitchens from recycled timber and describes him as “amazingly resourceful.” Paul learnt his trade building houses on rural properties, and then fitting them out with timber doors, windows and cabinets, all made on site without machinery.

“I was never [Paul’s] formal apprentice. We each had our own businesses and I would bring him in to help me on the harder jobs and show me how to do them properly. He would get me in (on a much lower hourly rate) when he had a big job and needed someone to help him. We were close friends for a long time and worked together for about 8 years on and off. Paul died in 2015 and is buried in Gundaroo. I usually stop by his grave if I’m out that way.”

Running a successful business is a huge accomplishment, especially when the organisation is environmentally conscious, creatively forward-thinking and employs some of the community’s most talented people. We asked Thor to tell us about a moment he is most proud of to date.

“I’m proudest of moving the business from the old Brickworks in Yarralumla, and how well the new set up and conversion of the Tip Top Bakery has worked out. All that planning and design work, thinking about how to minimise the disruption of the move, and make the new site flow smoothly for our production.

And the whole time you are worried you’ve missed something or made a big mistake. In the end we only shut down for one day.

“Thor’s Hammer was born out of a need to help increase awareness of the value of recycled timber, and thus a demand for recycled Australian hardwoods and an appreciation for its quality, beauty and history.”

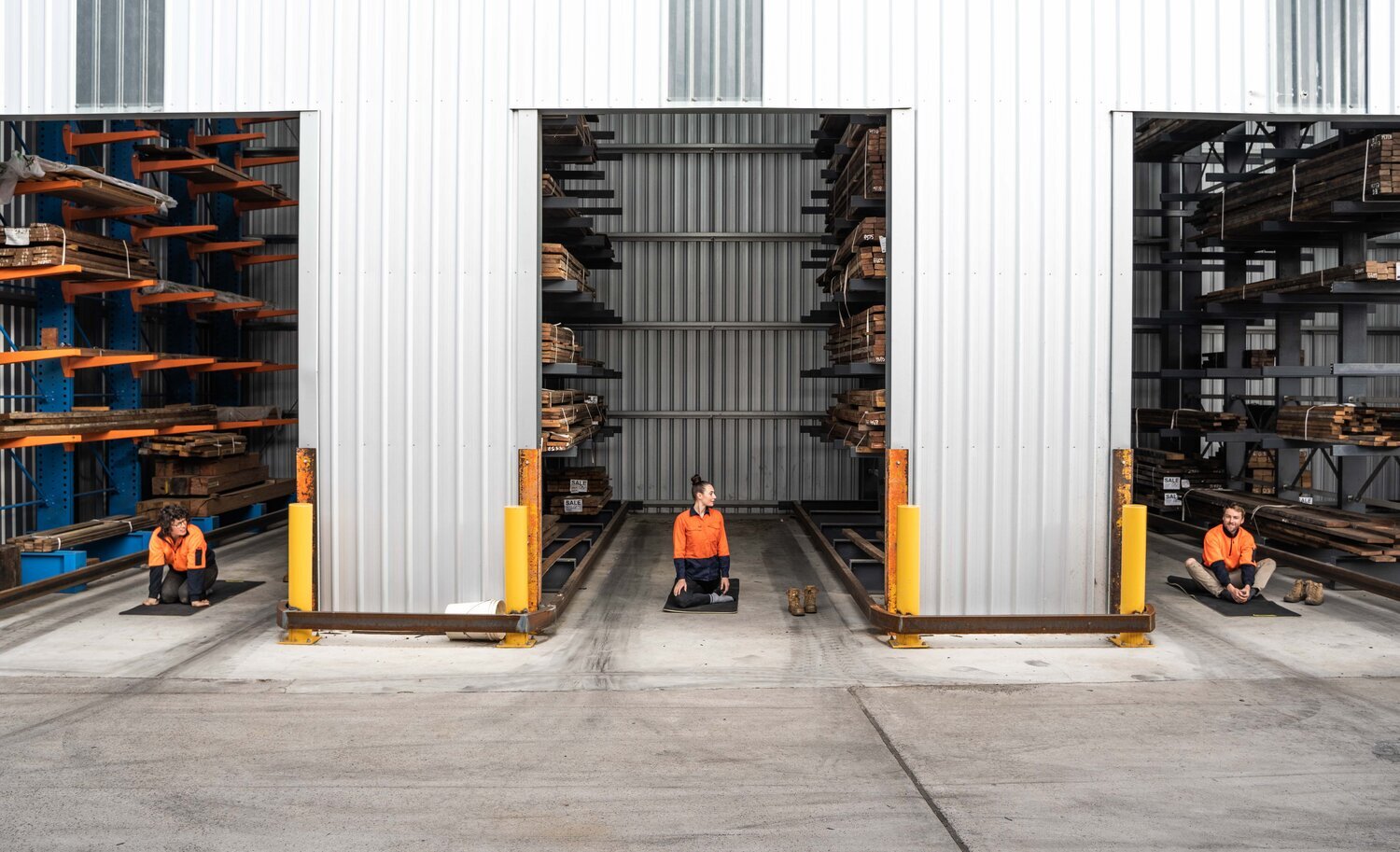

Thor pictured with team members in Yarralumla, ACT.

Thor’s Hammer is widely known in the community as having a collaborative work environment and being an enjoyable place to work, so we asked Thor why he thinks that may be and what he does differently to accomplish such a positive reputation.

Teamwork and collaboration is a huge part of what makes Thor’s business run so cohesively.

“Learning and growing - there is so much to learn here! We do the whole process with the timber from when it arrives from the demolition. From de-nailing, sorting and grading by the Recycling Team, to profiling and sawing with the big machines by the Dressing Team, to bench top and furniture making in the Joinery. People start with one team and then after a year or two can change into a different team if they want to learn more. In the joinery there are easily 5 years just getting started on all there is to learn. And then in the Sales & Design team, you need to have a handle across the whole business.”

Thor often shares his knowledge with the community by hosting workshop tours.

One of the more universally uncommon, yet much-loved approaches that Thor uses to encourage team building is spending quality and fun time together in the mornings.

“Morning stretches and handball are a good chance to catch up with everyone before we get stuck into the day, and make sure our bodies are warmed up, ready to concentrate before getting on the tools. That's 20 minutes each morning and it really adds something to the day.”

Thor says that another reason for the great work environment is getting the chance to be productive and see something for your effort at the end of every single day.

“Being a carpenter, my mentor Paul was big on efficiency and productivity. We were always thinking and brainstorming and trying to work out a better way, and then we’d get down to it and work hard. He showed me how much fun it is to work together and really produce and I’ve tried to keep that vibe at Thor’s Hammer.”

“It’s also just really satisfying for everyone in the team to be part of the recycling process, to know that they are part of saving good timber from landfill and to see how beautiful the finished product is. Our recycled Australian hardwoods are really special.”

Every maker, designer and artist has a design process, whether conscious routines or unconscious habits. We asked designer and maker, Thor, about what his design process entails.

“If I’m designing something completely new or difficult then I often do my best work at home on a day off.

I’ll think and do some drawings for an hour or so, and then head outside and do some gardening. When I go back inside I’ve usually made some good progress on the design while I weeded the garden!”

Thor’s current project is a new table base he’s been working on with joinery manager, Danilo Enders. Stay tuned to see it’s release in the coming weeks!

“Within 26 years we’ve become one of the largest timber suppliers in Canberra. All with recycled timber. I’m proud of that.”

Thor has engaged a team that is hard-working, creative and collegial, even the non-human ones.

Ziggy is a Samoyed cross (maybe!) with a Kelpie. Named after Ziggy Stardust, the four-legged team member is fluffy, gentle and comes into work most days. Although Ziggy isn’t the most productive team member, spending most of the day lounging in the corner of the workshop, she rewards the team with her company during breaks, lunch and morning stretches, and sometimes, head pats.

Thor speaks about the importance of a balance between work and leisure and how he makes time for physical activity and quality time with family and friends, whilst making sure that Thor’s Hammer continues to thrive and develop.

“These days a lot of my work is on the computer - running the business and designing using CAD - so after-work physical stuff is high priority.

I like to run through the arboretum and on the hills around Canberra. I’ve done Tough Mudder twice. It combines running and tree climbing type skills and has a great friendly vibe. So much fun getting muddy and helping each other through the obstacles!

In winter it’s backcountry skiing. A few years ago I spent 3 weeks camping out in the snow, that was amazing. I’d like to do a whole winter one day. It is so beautiful in the Snowies, the weather always throws something different at you and there is no stress up there. Just the basic human things we evolved doing, and that keep us happy. Walking all day. Finding your way. Using your body skilfully.

Last year I was really lucky to get introduced to rock climbing just before lock down. A friend took me to Arapiles (one of the top places in Australia for climbing). My housemate at the time, ‘Sausage,’ is a big climber so we managed to keep climbing most of last year, as long as we could exercise as a household. Rock climbing is very interesting physically and mentally. I’m really just getting started on it.”

Thor has many hammers, and this one is his favourite.

The final question I asked Thor, is one he says he often gets asked; how did Thor’s Hammer get its name?

“In the early days when we used to do a lot of salvage from demolition sites I was often using a sledge hammer to knock apart timber roofs or sub floors. Other trades on site used to think it was funny to yell out, "Thor, where's your hammer?!” (My generation grew up with Thor in the Marvel comic books). The hammer a key tool for salvage, for pulling out nails, and for carpentry and joinery, and so I decided to take that on and make it the business name.”

The team at Thor’s Hammer, 2019.

Story written by Irina Agaronyan